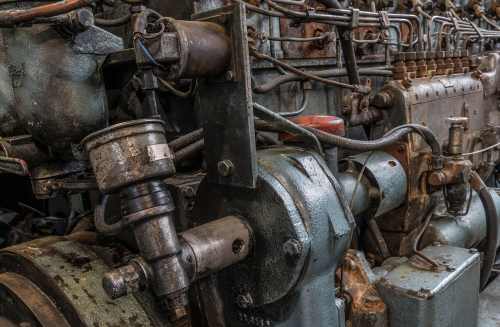

Corrosion at welded joints is one of the most common and costly challenges in industrial and structural metalwork, affecting everything from pipelines to bridges and manufacturing equipment. These joints are particularly vulnerable because the welding process alters the metal’s microstructure, creating heat-affected zones and residual stresses that can accelerate deterioration. Left unchecked, corrosion at these critical points can compromise structural integrity, reduce service life, and lead to expensive repairs or replacements. Understanding the mechanisms behind this type of corrosion is essential for businesses and engineers who aim to maintain the safety and longevity of their assets. Implementing effective corrosion protection solutions, including incorporating VCI technology and regular inspections, can significantly reduce these risks. By recognising the factors that contribute to weld corrosion and applying targeted prevention strategies, organisations can safeguard their infrastructure, enhance operational efficiency, and minimise maintenance costs over the long term.

Understanding Corrosion Mechanisms at Welded Joints

Corrosion at welded joints occurs due to a combination of metallurgical changes and environmental exposure introduced during the welding process. When metal is welded, intense heat is applied locally, causing alterations to the material’s microstructure. This creates a heat-affected zone (HAZ) adjacent to the weld, where the metal may have different chemical and mechanical properties compared to the base material. In many metals, particularly carbon steel and stainless steel, this change can significantly reduce corrosion resistance.

One of the most common issues at welded joints is localised corrosion, including pitting and crevice corrosion. Surface irregularities such as weld beads, undercuts, and micro-cracks can trap moisture and contaminants, creating ideal conditions for corrosion to initiate. Over time, these localised attacks can penetrate deeply into the material, often progressing unnoticed until structural integrity is compromised.

Residual stresses introduced during welding also play a critical role. As welded metal cools and contracts, tensile stresses can remain locked into the joint. In aggressive environments, these stresses increase susceptibility to stress corrosion cracking, particularly in industries exposed to chemicals, high temperatures, or marine conditions.

In stainless steel welds, improper thermal control can lead to sensitisation, where chromium carbides form along grain boundaries. This reduces the availability of chromium needed for corrosion resistance, making the welded area far more vulnerable than the surrounding metal. Understanding these corrosion mechanisms is essential for selecting appropriate welding techniques and long-term protection strategies.

Factors Influencing Corrosion at Welded Joints

The rate and severity of corrosion at welded joints are influenced by a combination of material, environmental, and operational factors. Understanding how these elements interact is essential for predicting corrosion risk and implementing effective prevention measures.

Material selection plays a significant role in weld corrosion performance. Different metals respond differently to the thermal stresses of welding, and incompatibility between the base metal and filler material can reduce corrosion resistance. For example, carbon steels are more susceptible to uniform and localised corrosion, while stainless steels can suffer from sensitisation if incorrect welding procedures are used. The quality of the weld itself is equally important, as inconsistencies in penetration or composition can create weak points where corrosion is more likely to initiate.

Environmental exposure is another critical factor. Welded joints located in marine, industrial, or high-humidity environments are exposed to moisture, salts, and airborne contaminants that accelerate corrosion processes. Chemical exposure in processing facilities can further intensify degradation, particularly when protective coatings are damaged or absent at the weld site.

Operational conditions also contribute to corrosion risk. Mechanical loading, vibration, and thermal cycling place additional stress on welded joints, increasing the likelihood of crack formation and corrosion propagation. Without appropriate post-weld treatments and ongoing maintenance, these combined factors can significantly shorten the service life of welded structures and equipment.

Common Welding Defects That Accelerate Corrosion

Welding defects are a major contributor to corrosion at welded joints, as they create surface irregularities and internal weaknesses that allow corrosive agents to penetrate the metal more easily. Even minor imperfections formed during the welding process can significantly increase the likelihood of premature deterioration if they are not properly identified and addressed.

One of the most common defects is porosity, which occurs when gas becomes trapped in the weld metal as it solidifies. These small voids can collect moisture and contaminants, forming ideal initiation points for localised corrosion. Undercutting, where grooves form along the edge of the weld, reduces the effective thickness of the metal and creates crevices that retain water and corrosive substances. Over time, these areas are particularly prone to pitting and crevice corrosion.

Slag inclusions and lack of fusion are also problematic, as they interrupt the continuity of the weld and create pathways for corrosion to spread beneath the surface. In more severe cases, micro-cracks can develop due to rapid cooling or excessive residual stress. These cracks allow corrosive media to penetrate deep into the joint, accelerating corrosion and increasing the risk of structural failure.

Addressing welding defects through proper technique, inspection, and quality control is essential for minimising corrosion risk and ensuring the long-term durability of welded structures.

Corrosion Mitigation Strategies for Welded Joints with VCI Protection

Mitigating corrosion at welded joints requires targeted protection methods that address both surface exposure and hard-to-reach areas where corrosion commonly initiates. While traditional coatings and treatments remain important, volatile corrosion inhibitor (VCI) strategies offer a highly effective supplementary solution, particularly for enclosed or complex welded assemblies.

VCI technology works by releasing corrosion-inhibiting molecules that migrate through the air and form a protective molecular layer on metal surfaces, including welded joints and heat-affected zones. This makes VCIs especially valuable where coatings may be difficult to apply evenly, such as internal cavities, boxed sections, pipelines, and complex weld geometries. The protective layer interferes with electrochemical corrosion reactions without altering the physical or mechanical properties of the metal.

At welded joints, VCIs provide protection against common corrosion mechanisms including pitting, crevice corrosion, and galvanic corrosion. They are effective on both carbon steel and stainless steel welds and can be delivered in multiple formats, such as VCI emitters, coatings, or impregnated packaging materials. This flexibility allows VCI strategies to be tailored to fabrication, storage, transportation, or in-service protection requirements.

VCI solutions are often used alongside conventional corrosion protection methods. When combined with high-performance coatings, proper weld preparation, and routine inspections, VCIs help extend the lifespan of welded structures and reduce maintenance demands. Their ability to protect concealed welds and inaccessible areas makes them a valuable component of modern corrosion protection strategies, particularly in industrial, marine, and infrastructure environments where long-term reliability is critical.

Inspection and Maintenance Best Practices for Welded Joints

Regular inspection and proactive maintenance are essential for managing corrosion at welded joints and ensuring the long-term reliability of welded structures. Because corrosion often initiates beneath coatings or within concealed areas of a weld, early detection plays a critical role in preventing extensive damage and costly repairs.

Non-destructive testing (NDT) methods are commonly used to assess the condition of welded joints without compromising structural integrity. Techniques such as ultrasonic testing, radiographic inspection, and dye penetrant testing can identify surface-breaking defects, internal flaws, and early-stage cracking that may accelerate corrosion. Visual inspections also remain important, particularly for detecting coating breakdown, discolouration, or surface irregularities around welds.

Maintenance strategies should be tailored to the operating environment and exposure conditions. Welded joints in marine or industrial settings may require more frequent inspections due to constant exposure to moisture, salts, and chemicals. Where corrosion protection systems such as coatings or VCI solutions are in place, regular checks ensure these measures remain effective and have not been compromised during operation.

Implementing a structured inspection and maintenance schedule allows asset owners to address minor issues before they escalate. This approach not only extends the service life of welded components but also improves safety, reduces unplanned downtime, and supports compliance with industry standards and asset management requirements.

Looking for Corrosion Protection Solutions?

Look no further than Australian Inhibitor. Corrosion at welded joints poses a significant risk to the safety and longevity of metal structures and assets across many industries. By understanding corrosion mechanisms and implementing effective corrosion protection solutions, VCIs and regular maintenance, organisations can minimise deterioration, extend asset life, and reduce long-term repair and replacement costs.

Get in touch by calling 03 9768 2322 or fill in our online contact form and we will get back to you.

Frequently Asked Questions About Corrosion at Welded Joints

Why are welded joints more prone to corrosion than base metal?

Welded joints are more susceptible to corrosion because the welding process alters the metal’s microstructure and creates a heat-affected zone with different chemical and mechanical properties. Residual stresses, surface irregularities, and welding defects can further reduce corrosion resistance, making these areas more vulnerable than the surrounding base metal.

What types of corrosion commonly occur at welded joints?

Welded joints are most commonly affected by localised corrosion such as pitting and crevice corrosion, as well as stress corrosion cracking. In stainless steel welds, sensitisation can also occur, increasing susceptibility to intergranular corrosion.

Can corrosion at welded joints be prevented?

While corrosion cannot be eliminated entirely, it can be effectively managed and significantly reduced. Proper material selection, controlled welding procedures, post-weld treatments, protective coatings, and corrosion protection solutions such as VCIs all play an important role in extending the service life of welded joints.