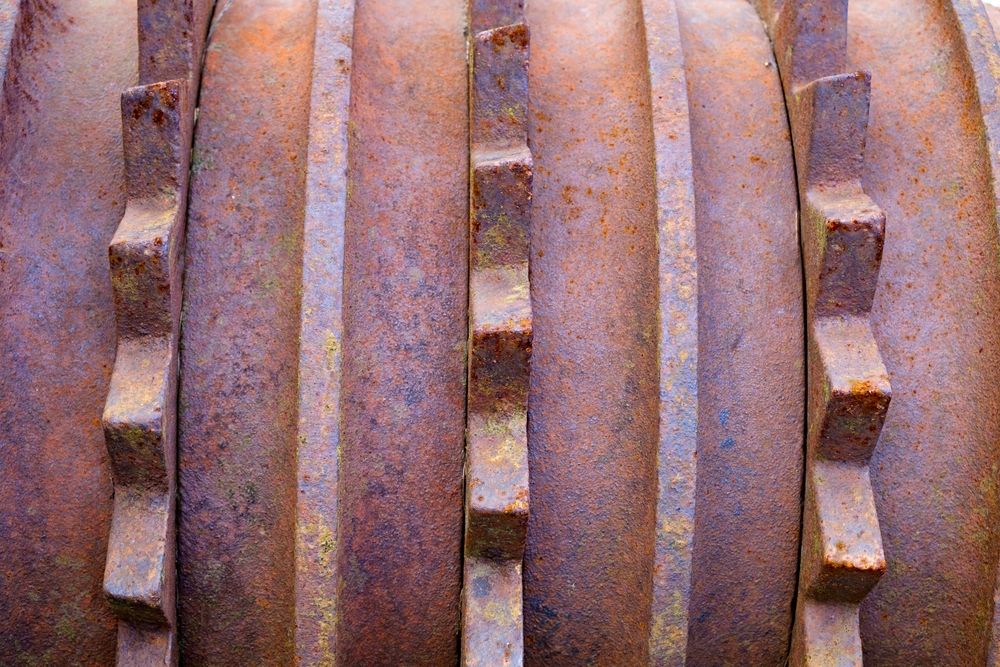

Corrosion might seem like a slow, inevitable process—a bit of rust here, some degradation there. But for businesses across Australia, particularly those in manufacturing, mining, transport, marine, and defence, corrosion is far more than a surface issue. It represents a significant and often hidden cost that can erode profits, disrupt operations, and reduce asset lifespan. Fortunately, Vapour Corrosion Inhibitor (VCI) technology offers an efficient, cost-saving solution that pays dividends in both the short and long term. This month, we explore the hidden financial impacts of corrosion and why investing in corrosion inhibitor solutions is a smart move for Australian industries.

The Real Cost of Corrosion

In Australia, industries lose billions each year to corrosion-related issues such as equipment failure, production downtime, safety risks, and maintenance expenses. But the costs of corrosion aren’t always obvious; they can be disguised as routine expenses or written off as unavoidable. Here are some of the key areas where corrosion takes a financial toll:

- Unscheduled Downtime

When machinery or equipment fails due to corrosion, operations have to stop. In sectors like mining or manufacturing, even a few hours of unplanned downtime can cost tens of thousands of dollars.

- Premature Equipment Replacement

Corrosion significantly reduces the lifespan of metal components. Replacing parts or entire systems earlier than expected means higher capital expenditure.

- Increased Maintenance Costs

Regular rust removal, part replacements, and repairs become necessary to manage corrosion. These recurring costs add up over time and strain maintenance budgets.

- Safety and Liability Risks

Corroded infrastructure poses safety hazards. Whether it’s weakened supports, degraded pipelines, or compromised tools, corrosion increases the risk of workplace accidents and associated liability costs.

Why VCI is a Smart Investment

VCI products work by emitting corrosion-inhibiting molecules that form a protective layer on metal surfaces. This barrier prevents the chemical reactions that cause rust and degradation. Here’s how this technology translates into real savings:

- Extended Asset Lifespan

By preventing corrosion at the molecular level, VCI helps keep metal components in prime condition for longer. This defers the need for replacements and preserves capital investment.

- Reduced Maintenance

With effective corrosion prevention in place, the frequency and intensity of maintenance activities drop. Labour hours, part replacements, and contractor fees can all be reduced.

- Minimised Downtime

VCI protection ensures that equipment stays in ready-to-use condition, particularly when stored for extended periods. This reduces the risk of start-up delays and operational interruptions.

- Protection During Storage and Transit

Whether you’re storing metal parts in a warehouse or shipping goods overseas, VCI protection provides continuous defence against environmental exposure without the need for constant monitoring or reapplication.

Sustainability Benefits = Financial Benefits

VCI products are increasingly designed with eco-conscious businesses in mind. Many VCI papers are recyclable and made from biodegradable materials, while VCI films can be reused or recycled depending on the application. By using clean, dry storage methods and avoiding harsh chemicals, companies can reduce their environmental footprint—often while complying with increasingly strict Australian environmental regulations. Lower waste, cleaner processes, and reduced chemical usage don’t just help the planet—they also reduce spending on waste management and regulatory compliance.

How to Maximise ROI from VCI

Maximising your return on investment (ROI) from VCI technology starts with a well-planned strategy and consistent implementation. To fully realise the financial benefits of VCI protection, businesses should:

Choose the right product for the application: VCI oil might be perfect for heavy-duty mining gear, while VCI paper is ideal for small components. Consider the material type, the duration of storage, and the environmental conditions your products will face. Matching the VCI solution to your specific operational needs will maximise efficiency and longevity.

Train staff in best practices: Proper wrapping, sealing, and handling techniques ensure maximum effectiveness. Staff should understand how VCI works and the importance of maintaining clean, dry surfaces before application. A simple oversight, such as leaving a package unsealed, can negate the protection VCI provides.

Inspect and review regularly: Regular audits help ensure that your VCI program is delivering the expected cost savings and protection. Look for signs of wear, packaging damage, or areas where corrosion may still be occurring. Addressing small issues early prevents larger financial setbacks down the line.

Work with a corrosion prevention expert: Custom solutions can be developed to fit your industry and climate, ensuring optimal performance. Experts can help with on-site evaluations, product recommendations, and tailored training to ensure your team is using VCI effectively. Their insight can uncover new opportunities to save money and improve long-term asset reliability.

Do You Need Corrosion Inhibitor Solutions for Your Assets?

Look no further than Australian Inhibitor for your corrosion inhibitor needs. We are backed by over 65 years of experience and are here to help with corrosion protection for your valuable metal assets. In addition, we are proud to offer all of our customers our signature exceptional customer service.

Contact us by calling 03 9768 2322 or filling in our online contact form and we will get back to you.